A Tale of Two Hub Assemblies: Why the Journey Matters

A Tale of Two Hub Assemblies

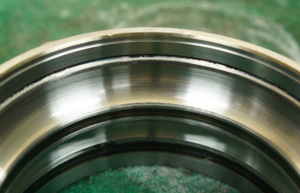

The journey a hub assembly takes to your shop is remarkable when you think about it, from the inception of a vehicle platform, engineering of the bearing application by an OE bearing manufacturer, to the transport of the wheel hub to the factory. Now it is in your bay and damaged by thousands of miles of rough roads.

These are two replacement hub assemblies. The first one is made by NTN, which is an OE supplier and parent company of the BCA Bearings by NTN aftermarket brand. The second hub assembly arrived in a white box with a 3” x 4” sticker displaying the part number and barcode. Both of these hub assemblies have had their own journeys, but they have very different beginnings.

BCA Bearing Journey

As the largest OE supplier of wheel hubs, being present at the birth of a vehicle platform gives NTN a competitive edge and you a better bearing in the aftermarket from their BCA brand. This very specific OE engineering information helps BCA to deliver a part that not only meets OE requirements but also exceeds your expectations—even items you can’t see, like metallurgy, micro finishes and machined tolerances.

When it comes to hub units, there are other hidden heroes like the bearing cage, grease, seals, wheel speed sensors and wiring harness. These items are engineered as a system for the application for the best longevity of the unit. How does BCA know? Countless hours of product development in cooperation with the OEM and the input of technicians.

BCA supports technicians in the field with videos, webinars and live technical support. This training resource has helped many technicians to level up their skills and the knowledge to tackle just about any wheel-end repair.

White Box Journey

Cheap hub assemblies are typically reverse-engineered. This means when they need to add an application to their catalog, they will obtain the hub assembly and measure the physical dimensions using tools like a parts scanner. But, even the most accurate scanner can’t capture critical measurements like manufacturing tolerances, depth of the heat treating or the quality of the materials for the seal.

The metallurgy also matters. Many manufacturers start with steel that might have contaminants that can cause inclusions. Not only will the replacement unit have low-quality steel, but the manufacturer might cut costs by reducing heat-treating periods or not allowing the steel to properly cool down slowly to avoid stresses in the castings. Heat treating is a precision process that is expensive and time-consuming, so cutting corners here is an easy way to cut costs (and quality). Either way, the inclusions and poor heat treatment could cause a premature failure.

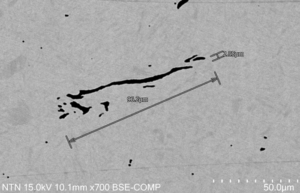

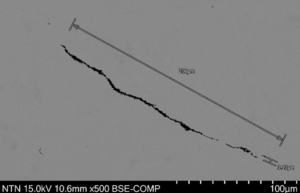

These white box product samples failed NTN’s Test Lab tolerances for non-metallic inclusions caused by low-quality steel,

and poor grain structure transition caused by poor heat treatment.

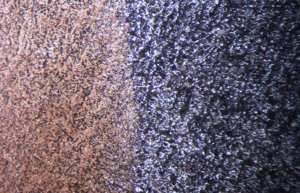

Another time consuming process where corners can be cut is grinding and polishing of the rolling elements and raceway surfaces. After heat treatment, these components are ground, polished, and super-finished using a progressive process that produces highly polished surfaces. These surfaces are critical for friction reduction and have a big impact on the longevity of the bearing assembly. You never see these surfaces, unless the bearing suffers a catastrophic failure, so you have to trust it was done to spec, but with the white box product, you have no way of knowing.

These white box product samples failed NTN’s Test Lab tolerances for Raceway Surface Roughness

due to scratches and roughness caused by insufficient finishing processes.

The other surprise in the white box could be the wheel speed sensor and attached harness. In the past, low-quality hub assembly manufacturers could get away with wheel speed sensors that were close to the original. But advancements in sensor technology and accuracy for advanced driver assistance systems (ADAS) have proven that close is not good enough for some applications. The wiring harnesses should also include application specific grommets and abrasion sleeves that ensure secure and long lasting installation, and this is not always the case with white box products. For your shop, it could cause a comeback due to false activations of an ADAS system and multiple warning lights.

Don’t expect support in the field or training. All these low-quality brands are just a part of a box with very little commitment to you or your customers.

Why does the journey matter more than the destination?

The engineering of a hub assembly at the OE level involves engineering a part that meets the requirements for the platform or vehicle. Low-quality manufacturers engineer an application to match an original hub assembly without the benefit of OE specifications. They use lower quality materials, cut corners on manufacturing processes, and use less intensive quality control. The cheap manufacturers can get the ball on the green, but the BCA hub assembly puts the ball in the hole.

The other advantage is the longevity of the repair. Due to non-OE engineering information and manufacturing processes, the reverse-engineered bearings will not last as long as a true, OE-quality BCA wheel hub assembly.