ASK MATT Q&A

BCA’s “Ask Matt” feature answers the common wheel hub and bearing questions that we get from technicians and DIYers.

INSIGHTS FROM AN INDUSTRY EXPERT

ABOUT MATT

Matt Gorski is NTN's Manager of Product Development for the Automotive Aftermarket.

Matt is a car guy who spends his free time wrenching on cars, and can often be found under the hood of a vehicle belonging to a friend, neighbor, or co-worker. He is the go to guy when you have a service indicator light on, or hear your car making a weird noise.

Matt started out in the automotive industry as an auto technician. He worked as an auto tech for 12 years before joining the automotive aftermarket as a technical trainer, and then moved into product management.

Matt’s experience in the automotive aftermarket and as a technician makes him a great resource for end-users, technicians and countermen alike.

ASK MATT Q&A - INSIGHTS FROM AN INDUSTRY EXPERT

Topic: Resistance When Rotating New Wheel Bearings

QUESTION: Why do wheel bearings feel rough or hard to rotate when new out of the box?

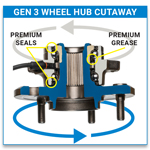

ANSWER: This is an a common inquiry from from technicians and DIYers. During initial use, it is normal to feel resistance or grittiness as the wheel bearings rotate. This tightness is the result of tight manufacturing tolerances and the premium grease and seals that we use in our bearings. The premium grease used in BCA’s bearings contains performance enhancing additives, which are crystalline in structure, and can cause a rough feeling and rotational resistance when the bearing is new. The crystalline structure of the grease will breakdown into finer elements when driving a vehicle, so the rough initial rotation will smooth out.

Learn more in our BCA Tech Tip Here: https://bcabearings.com/techtips/resistance-when-rotating-new-bearings/

Topic: Tesla Model S & Model X Wheel Bearing Replacement

QUESTION: I am installing a BCA WE61960 on the front of a single-motor, RWD Tesla Model S. It has an open center and splines to fit a dual-motor, AWD Model S. Is this the correct bearing for the application?

ANSWER: Yes. The BCA WE61960 is the correct bearing for both the single- and dual-motor Model S in the front and rear. The splined center opening in the hub does not impact the hubs function or performance in any way when installed on the front of the RWD, single motor models. The bearing preload is set at the factory using orbital forming. This cold process rolls the lip of the inner race to permanently set the specified preload on the hub bearing. There is no need for an axle nut to set the preload when there is no CV axle.

Topic: Tesla Model S & Model X Wheel Bearing Replacement

QUESTION: Is it necessary to disconnect the high voltage battery to service the wheel bearings?

QUESTION: Is it necessary to disconnect the high voltage battery to service the wheel bearings?

ANSWER: No. The highest voltage you will come in contact with is 12 volts of direct current from the wheel speed sensor. Just make sure the car is in tow mode. There is not any need to disconnect the 12-volt or high voltage batteries.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/what-do-you-need-to-know-about-tesla-model-wheel-bearing-replacement/

Do you have a question about automotive wheel hubs, bearings or seals?

Use the form at the bottom of the page to submit your question(s). Your question may be featured in an upcoming "Ask Matt" column, as well as right here on the BCA website.

Topic: Hybrid and EV Wheel Bearings

QUESTION: We know that Hybrid Electric Vehicles (HEVs), Plug-In Hybrid Vehicles (PHVs), and Electric Vehicles (EVs) are heavier than comparable gasoline powered vehicles. Can this have any effect on the lifetime and performance of the wheel bearings?

QUESTION: We know that Hybrid Electric Vehicles (HEVs), Plug-In Hybrid Vehicles (PHVs), and Electric Vehicles (EVs) are heavier than comparable gasoline powered vehicles. Can this have any effect on the lifetime and performance of the wheel bearings?

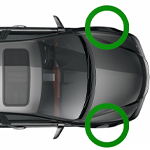

ANSWER: Absolutely, the service life of a wheel bearing in one of these vehicles could be shorter. The added curb weight needs to be supported by the suspension and chassis, and this can take a toll over time. The bearings could be more susceptible to damage from an impact, whether it’s a curb strike or a nasty pothole.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/understanding-electric-hybrid-vehicle-wheel-bearings/

Topic: Hybrid and EV Wheel Bearings

QUESTION: Is there a fundamental difference between the wheel bearings on a BEV or EV versus a comparable gasoline-powered vehicle, or are they nearly the same?

QUESTION: Is there a fundamental difference between the wheel bearings on a BEV or EV versus a comparable gasoline-powered vehicle, or are they nearly the same?

ANSWER: No, in most cases they’re the exact same. Some OEMs have experimented with adding rows of ball bearings to help carry the added weight, but it’s not common.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/understanding-electric-hybrid-vehicle-wheel-bearings/

Topic: Tapered Roller Bearings

QUESTION: What is the terminology for the two parts that make up a tapered roller bearing set?

QUESTION: What is the terminology for the two parts that make up a tapered roller bearing set?

ANSWER: Tapered Roller Bearings are generally packaged as a two-piece, matched set.

The inner bearing assembly contains the rollers, bearing cage and inner race, and is referred to as the cone, or more commonly just called the bearing.

The outer ring of the bearing set is referred to as cup, outer race, or commonly just the race. The race is a single piece with no moving parts.

The outer ring of the bearing set is referred to as cup, outer race, or commonly just the race. The race is a single piece with no moving parts.

When used as a set, the bearing will seat inside of the race, which sandwiches the rolling elements and cage between the inner and outer race.

Topic: Tapered Roller Bearings

QUESTION: Tapered bearings have been in use for decades, but they’ve fallen out of use in common applications in favor of bearing styles which are more economical for OEMs. So, do tapered wheel bearings have anything to offer over other types of bearings?

QUESTION: Tapered bearings have been in use for decades, but they’ve fallen out of use in common applications in favor of bearing styles which are more economical for OEMs. So, do tapered wheel bearings have anything to offer over other types of bearings?

ANSWER: Absolutely, tapered bearings are designed for high axial, radial and combined load capacities. They can cope with heavier loads thanks to the large contact area between the rollers and the rings. They’re not very costly to manufacture, and they’re extremely well suited for commercial vehicles as well as medium to heavy duty trucks.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/tapered-roller-bearings-for-wheel-end-applications/

Topic: Tapered Roller Bearings

QUESTION: What should technicians keep in mind whenever servicing this type of bearing?

QUESTION: What should technicians keep in mind whenever servicing this type of bearing?

ANSWER: Thoroughly clean the bearing races and surfaces, any contaminants or debris could potentially shorten the service life of the bearings. The bearing cup and the cone experience wear together and should always be replaced at the same time. The bearings need to be greased by hand during install, commonly known Instead, they need to be greased by hand when installed, commonly referred to as “hand-packing”.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/tapered-roller-bearings-for-wheel-end-applications/

Topic: Wheel Hub Assemblies

QUESTION: Some vehicle models change the wheel bearings used by the OEM in the middle of model year. When this happens, how do you determine which aftermarket parts fit the vehicle?

ANSWER: When this occurs, the BCA catalog will specify the production month and year that the part change took place. The production month and year of a vehicle can be found on the manufacturers placard, which can be located inside the driver’s doorjamb.

For example, a 2003 Toyota Sienna will use either a WE60770 or WE61918 for the rear wheel bearing. If the vehicle was produced BEFORE or INCLUDING 01/2003 then it uses the WE61918. If the vehicle was produced AFTER 01/2003 then it uses the WE60770. A quick check of the vehicle production date will determine the correct part to use.

Topic: Wheel Hub Assemblies

QUESTION: Is the BCA WE60884 the correct front hub assembly for a 2007 Silverado 2500 Classic RWD? The catalog lookup says it is driven, but the truck is rear wheel drive.

ANSWER: Yes, the BCA WE60884 is the correct Front Hub Assembly for the 2007 Silverado 2500 Classic RWD. The reason this hub is listed as “driven” is because the hub has axle splines on the inner bore. The hub is splined because the RWD and 4WD models use the same front hub assembly.

It is also worth mentioning that we encourage installers to be absolutely sure they are dealing with the “Classic” model for the 2007 Silverado. The wheel hubs for the classic and new models look the same and will fit each other, but they contain different wheel speed sensors, and if a new version is installed on a Classic model (or vice versa), it will trigger the ABS light.

Topic: Wheel Hub Assemblies

QUESTION: Does the BCA WE61564 Wheel Hub Assembly come with the wheel studs installed?

ANSWER: Yes, the BCA WE61564 hub assembly comes with 8 premium quality wheel studs permanently installed in the wheel mounting flange. If our product image shows wheel studs installed in the hub assembly, that is how the part comes in the box, ready to install.

Topic: Seals

QUESTION: Are there any other components we should replace along with the bearings?

QUESTION: Are there any other components we should replace along with the bearings?

ANSWER: It’s best practice to always replace the seals when replacing bearings. The seals are responsible for keeping outside contaminants away from the bearing surfaces.

Topic: Seals

QUESTION: I am installing a BCA WE60630 on the front of a 2005 Subaru Impreza WRX. Do I need to buy separate seals or is the bearing a sealed unit?

ANSWER: The BCA WE60630 is not a sealed bearing. For this application, you need to purchase an inner and outer wheel seal. The BCA NS710464 is the front inner wheel seal for a 2005 Subaru Impreza WRX and the BCA NS710463 is the front outer wheel seal. These seals are the unsung hero of the wheel end, retaining the lubrication for the wheel end and keeping contaminants out.

Do you have a question about automotive wheel hubs, bearings or seals?

Use the form at the bottom of the page to submit your question(s). Your question may be featured in an upcoming "Ask Matt" column, as well as right here on the BCA website.

Topic: Wheel Speed Sensors

QUESTION: Can I repair a wheel speed sensor wiring harness?

QUESTION: Can I repair a wheel speed sensor wiring harness?

ANSWER: It is not recommended to repair the harness that connects the wheel speed sensor to the vehicle’s harness for two reasons. First, since the wheel speed sensor is connected to the suspension, it must flex. Solder, butt connectors and heat shrink tubing can cause a stiff area of the harness that will not bend the same way. This can cause the wires on either side of the splice to fatigue and eventually fail. Second, any time the outer sheathing is cut, it can create an area for water intrusion. Water causes corrosion, which can change the circuit’s resistance.

Learn More in our BCA Video Tech Tip Here:

https://bcabearings.com/videos/repairing-wheel-speed-sensor-wiring-harnesses-part-1/

https://bcabearings.com/videos/repairing-wheel-speed-sensor-wiring-harnesses-part-2/

Topic: Wheel Speed Sensors

QUESTION: If a new hub unit comes with a wheel speed sensor and harness attached with a bolt, can I reuse the old sensor to avoid having to deal with the connector that might be behind a fender liner?

QUESTION: If a new hub unit comes with a wheel speed sensor and harness attached with a bolt, can I reuse the old sensor to avoid having to deal with the connector that might be behind a fender liner?

ANSWER: No, the air gap for the wheel speed sensor and encoder ring is set at the factory when the new hub unit is manufactured. Reusing the old sensor can change the air gap and cause chassis codes for erratic signal, comparative performance or other manufacturer specific codes related to the sensor’s output.

Topic: Magnetic Encoder Ring

QUESTION: The BCA WE60567 Wheel Hub Assembly says it is equipped with an ABS encoder ring, but the images don't appear to show one. Is this correct?

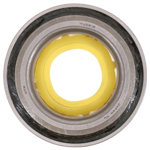

ANSWER: The BCA WE60567 Wheel Hub Assembly does contain an ABS encoder ring. In the case of this part, and many others like it, the magnetic encoder is built into the seal on the inboard side of the hub assembly, so the encoder is there, but it looks like a ordinary seal.

Topic: Magnetic Encoder Ring

QUESTION: I am installing a BCA Wheel Hub Assembly on a customer car, and when I was bolting it up to the vehicle, I scratched the magnetic encoder in a couple places. They look to be very light surface scratches and didn’t leave impressions or break the surface of the encoder. If this is installed would there be a fault code due to the scratches?

ANSWER: Light surface scratches should not interfere with the function of the magnetic encoder. You generally run into issues when there is a depression showing evidence that pressure has been applied to the encoder. This damage will change the magnetic signature of the encoder.

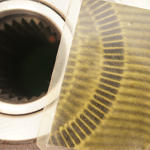

If there is any doubt as to the condition of the integrity of the magnetic encoder, checking of the condition of the magnetic poles with magnetic viewing film (see image at right) is a best practice. If that is not an option, purchasing a replacement hub assembly is always cheaper than redoing the job and having an unhappy customer with a comeback.

This is a good reminder to always take care when mocking up or installing a wheel hub assembly with an exposed magnetic encoder.

Topic: Gen 1 (or Cartridge Style) Wheel Bearings

QUESTION: The Gen 1 wheel bearing I am installing has magnetic encoder rings on both seals, which side encoder needs to go in towards the wheel speed sensor?

QUESTION: The Gen 1 wheel bearing I am installing has magnetic encoder rings on both seals, which side encoder needs to go in towards the wheel speed sensor?

ANSWER: For some applications, BCA has magnetic encoder rings on both side seals to eliminate the possibility of pressing the bearings backward. Both seals and encoder rings are the same on both sides.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/professional-tips-for-efficient-gen-1-wheel-bearing-replacement/

Topic: Gen 1 (or Cartridge Style) Wheel Bearings

QUESTION: Can I use a large socket to press a bearing?

QUESTION: Can I use a large socket to press a bearing?

ANSWER: No. Sockets typically have chamfered edges. This increased the possibility that the socket could slip off the outer race and make contact with the seals. Anytime a tool comes in contact with the magnetic encoder ring seal, damage can occur to the magnet poles embedded in the seal. You might only find out once the job is finished, and you go for the test drive, and the ABS light comes on. In a pinch the old bearing can be used to press the new bearing assembly into the bore of the knuckle. BCA strongly suggests investing in a good set of bearing/race installation tools.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/professional-tips-for-efficient-gen-1-wheel-bearing-replacement/

Topic: Gen 1 (or Cartridge Style) Wheel Bearings

QUESTION: When do I know a bearing has reached its final pressed-in depth?

QUESTION: When do I know a bearing has reached its final pressed-in depth?

ANSWER: A lot of applications use a snap ring to help retain the bearing in the knuckle bore. It is therefore important to be sure the bearing is fully installed and clears the groove the snap ring is installed into. This is why it is crucial to inspect, clean and deburr the bore of the knuckle before pressing the bearing into it ensuring it will fully seat and allow for the snap ring to be installed. Rarely an application will not use snap rings. The key is to press the bearing completely into the bore of the knuckle till it bottoms out. Again only after inspecting, cleaning and deburring the bore before pressing the bearing in. Another critical thing to remember is that the depth of the bearing determines the air gap between the magnetic encoder ring and the wheel speed sensor. If the bearing is not pressed in completely, there could be too much air gap and the wheel speed sensor may not sense the movement of the encoder ring’s magnets. As for the flange, remember the final depth is set when the axle nut is torqued. That is another reason to always torque all Gen 1 bearing application axle nuts to the proper specification.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/professional-tips-for-efficient-gen-1-wheel-bearing-replacement/

Topic: Axle Nut Torque

QUESTION: Where can I find axle nut torque specifications?

QUESTION: Where can I find axle nut torque specifications?

ANSWER: For many years, BCA has included a printed “Axle Nut Torque Specification Booklet” in the box with applicable wheel hub assemblies. We are currently planning to transition to a QR code-based solution, which will deliver the same torque spec info to the technician digitally. This new solution will also allow us to include additional installation info and tech tips to ensure the techs have the latest data and specs to ensure proper installation.

Topic: Axle Nut Torque

QUESTION: Where can you calibrate your torque wrench? Is it only for mechanical torque wrenches or for the electronic ones as well? Do you go to a tool dealer?

QUESTION: Where can you calibrate your torque wrench? Is it only for mechanical torque wrenches or for the electronic ones as well? Do you go to a tool dealer?

ANSWER: Any style of torque wrench of decent quality (Click, Beam, Digital, or Dial) can be calibrated. Many tool manufactures market their own torque wrench calibration tools, and professional tool dealers, like Snap On or Matco, sell the calibration equipment and also provide calibration services. You may also find reputable calibration services where you can send them your torque wrench for calibration and they send the calibrated tool back to you with a certificate of calibration.

Topic: Axle Nut Torque

QUESTION: The manufacturer torque spec for an axle nut on my install is 148ft lbs. The nut feels very tight, but the torque wrench hasn’t clicked. It seems like it should be tight enough, and I don’t want to overtighten the axle nut. Should I continue to tighten the axle nut until the torque wrench clicks or should I leave it as-is?

QUESTION: The manufacturer torque spec for an axle nut on my install is 148ft lbs. The nut feels very tight, but the torque wrench hasn’t clicked. It seems like it should be tight enough, and I don’t want to overtighten the axle nut. Should I continue to tighten the axle nut until the torque wrench clicks or should I leave it as-is?

ANSWER: We have been in this situation, where you keep tightening and waiting for the torque wrench to indicate the correct torque, and it feels like it should be tight enough.

Our advice is to always trust the torque spec! If you are using a properly calibrated torque wrench with the correct capacity, you should keep tightening the fastener until you reach the spec’d torque.

If you are unsure, it doesn’t hurt to stop and double-check the manufacturer spec, make sure your torque wrench is set correctly, and that the axle nut is threaded on properly. But if everything is correct, trust the spec.

Do you have a question about automotive wheel hubs, bearings or seals?

Use the form at the bottom of the page to submit your question(s). Your question may be featured in an upcoming "Ask Matt" column, as well as right here on the BCA website.

Topic: Axle Nut Torque

QUESTION: The 2016 Chevy Equinox is either AWD or FWD, and both use same rear wheel bearing, the BCA WE60837. Why is there no rear wheel bearing torque spec on the FWD model, but the AWD setup has torque spec?

ANSWER: In many applications, the axle nut torque specs exist to set the proper bearing preload. The rear wheel bearings on the Equinox have a rolled closure design that sets the wheel bearing pre-load from the factory. This means that the FWD models are able to use the same rear wheel bearings as the AWD models without needing a torqued axle nut because there is no axle nut to torque on the rear of FWD models. The AWD models with rolled closure designed hubs, still list a torque spec for the front and rear axle nuts; this torque spec is important for the retention of the axle, but do not set the bearing preload.

Topic: Axle Nut Torque

QUESTION: Can I use a digital torque wrench adapter, or are they not as accurate as a dedicated torque wrench?

QUESTION: Can I use a digital torque wrench adapter, or are they not as accurate as a dedicated torque wrench?

ANSWER: Digital torque wrench adapters can be a great, versatile tool, and in some cases can even be more accurate than a traditional torque wrench. Our philosophy is that a high quality tool in the hands of a qualified tech, being used properly is the way to go. We wouldn’t recommend a cheap version of unknown origin for critical torque specs, but a quality torque wrench adapter from a reputable tool supplier is a great solution.

Topic: Axle Nut Torque

QUESTION: Do the wheels of a vehicle need to be on the ground to properly torque down the axle nut?

QUESTION: Do the wheels of a vehicle need to be on the ground to properly torque down the axle nut?

ANSWER: No, the wheels do not need to be on the ground to properly torque the axle nut. However, on axles that rotate, like on a 4WD application, the axle needs to be secured so it will not turn while tightening the nut. Most technicians do this by putting a screwdriver or other such tool into the cooling vanes of the brake rotor to prevent rotation, or have someone depress the brake pedal to keep the axle from turning during tightening.

Topic: Axle Nut Torque

QUESTION: Do the front hubs on a 2011 Xterra 4x4 require preload from the axle nut? Or is the torque spec for the axle nut just to keep the axle tight? Could I theoretically run 4x4 hubs on a 2wd without issues?

ANSWER: Our BCA WE61172 hub assembly for the 2011 Nissan Xterra 4x4 model is designed with a “rolled closure”, which sets the preload on the bearing from the factory. The Nissan factory torque spec for the axle nut of 101 ft-lbs is to properly retain the axle in the splined hub, not to set the bearing preload.

Our BCA WE61213 hub assembly for the 2WD model also features a rolled closure design which sets the bearing preload, and since there is not axle nut, there is no torque spec needed.

We do not recommend the use of a part on a vehicle it is not spec’d for, like swapping the 4x4 part in place of the 2WD part. The mounting dimensions and bolt pattern may be the same, however for safety reasons we cannot recommend interchanging the parts. In this case we offer the coverage for both 4WD and RWD at similar cost and availability to accommodate both models.

Topic: Axle Nut

QUESTION: Do I need to replace the axle nut if the service information calls for it?

QUESTION: Do I need to replace the axle nut if the service information calls for it?

ANSWER: If the installation procedure says you need an axle nut, always replace the axle nut. The collar on the outside was distorted when it was first installed. As the nut is exposed to external forces, corrosion and heat, it loses its ability to secure the nut to the axle. When the nut is removed, often the nut is damaged. This is why you need to replace the nut for some applications.

Topic: Axle Nut

QUESTION: I can’t get the axle nut to budge! What are some tricks?

QUESTION: I can’t get the axle nut to budge! What are some tricks?

ANSWER: The best advice is to take your time and use the correct tools, like axle nut specific sockets. Penetrants like WD40, or my favorite PB Blaster, work wonders in loosening up stubborn, frozen or rusted fasteners. Using air or a cordless impact can work. But don’t use the impact for extended periods. The force (and repeated impacts) can damage the CV joints, differential and transmission. A breaker bar can often apply more torque than an impact on some applications. Another trick is to place a pipe over the handle of a socket wrench giving you an even greater mechanical advantage. Use of heat should be your last option! But look at the service information for the sequence and precautions for removing the nut.

Topic: Bad Wheel Bearing or Poor Alignment?

QUESTION: I had an alignment done, and afterwards the vehicle was pulling to the right. The alignment shop said it was likely being caused by the right front wheel bearing going bad. Will a worn-out front wheel bearing cause a vehicle to pull to the side?

QUESTION: I had an alignment done, and afterwards the vehicle was pulling to the right. The alignment shop said it was likely being caused by the right front wheel bearing going bad. Will a worn-out front wheel bearing cause a vehicle to pull to the side?

ANSWER: It would be rare for a failing wheel bearing to cause your car to pull to the right without first exhibiting other noticeable signs of failure, like noise and vibration. It would be far more common for a car to pull to one side because of an issue with the tires, brakes, worn suspension components, or a poor alignment. Suspension parts are generally inspected when doing an alignment, but uneven wear on the tires could be overlooked and might be more noticeable after an getting an alignment. We strongly recommend having all these components as well as the wheel bearings checked for wear and play.

Topic: Clicking Noises from Wheel Hub

QUESTION: Why is it sometimes recommended to use moly lube on axle splines/hub mating surfaces when installing a wheel hub or addressing a customer complaint about clicking noises?

ANSWER: A moly lubricant coating is sometimes recommended on axle splines, wheel hub mating surfaces and mounting flanges to eliminate clicking noises on acceleration or turning. These clicking noises are caused by microscopic movements of the contact surfaces, and the moly lube will eliminate the clicking noises this causes. It is recommended that you search for manufacturer TSBs when installing a wheel hub assembly or troubleshooting a customer complaint to determine if this is an issue for that application. In most cases the moly lube can be applied without fully disassembling the wheel end, making for a relatively simple repair job.

Learn More in our BCA Video Tech Tip Here: https://bcabearings.com/videos/are-you-getting-customer-complaints-about-clicking-noises-after-replacing-a-wheel-hub/

DO YOU HAVE A QUESTION?

Do you have a question about automotive wheel hubs, bearings or seals?

Use the form below to submit your question(s). Your question may be featured in an upcoming "Ask Matt" column, as well as right here on the BCA website. If we feature your question, we will send you a gift from BCA as a thank you for reaching out.