Tech Tips

Removing Stuck Wheel Bearings the Right Way

Whether you are an Automotive Technician or a DIYer, getting a job done in an efficient manner is important. One common issue that can occur when replacing a wheel hub assembly is difficulty separating the wheel hub assembly from the steering knuckle. Removing a stuck wheel hub can seem impossible at times. This quick tech tip should be helpful if you ever encounter this situation.

Wheel hubs are made of high-strength steel and the steering knuckle they are attached to is generally made of aluminum. This leads to a process called galvanic corrosion (bimetal corrosion). Galvanic corrosion is a naturally occurring process in which two dissimilar metals react with each other, essentially welding the wheel hub to the steering knuckle during their normal service life.

Tech Tip

When encountering difficulty separating a Gen 3 wheel hub from a steering knuckle, you may be tempted to resort to brute force, in the form of a heavy hammer or other tool, to break the bond loose. Using a heavy hand tool is often ineffective at breaking the galvanic bond, but even worse, can damage the steering knuckle or other steering/suspension components, compounding the issue.

It is also recommended that you never use a torch to heat the steering knuckle. While heat can be helpful in installing and removing bearings, a torch does not provide the precision needed to heat only the necessary components. This can damage or distort the knuckle and ball joints, and lead to collateral damage to other vulnerable components on the steering, suspension and brakes.

Use of an induction heater to heat the wheel hub assembly is the preferred method over using a torch. This will allow you to apply heat strategically to the wheel hub to break up corrosion and help penetrating oils to penetrate deeper, while isolating related components from damage.

If you do not have an induction heater that works for a wheel end application, or you just need more muscle to separate the wheel hub from the knuckle, you can use an air hammer to help. When using an air hammer to loosen a wheel hub, the key is not how much force you are using; it is how you are applying that force.

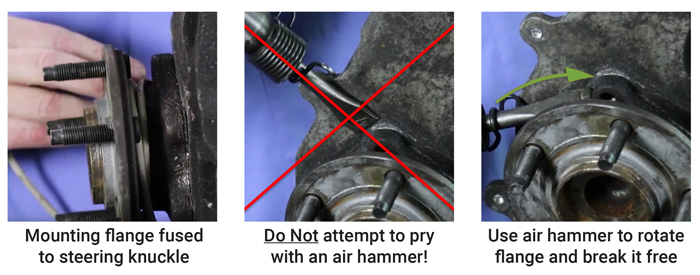

Do not try to use the air hammer as a wedge to pry or push the wheel hub free from the steering knuckle. It is virtually impossible to force the air hammer between the two components without damaging them.

Instead, you can use the air hammer to rotate the wheel hub mounting flange in relation to the steering knuckle, while avoiding contact with the knuckle. When the wheel hub starts to rotate, while the knuckle remains fixed in place, it will have broken free from the galvanic bond and will be much easier to remove.

Remember, if you damage adjacent components while replacing a wheel hub, the best case scenario is an extra call or visit to the auto part store as well as the job taking longer and costing more than planned. A much worse scenario is an angry customer or even a comeback if the damage isn’t identified before the vehicle leaves the shop. It pays to work smart!

Watch a Video Demonstration and Download a Tech Tip PDF Below: